1、四五十年前,所有阀芯式法兰橡胶膨胀节都是手工制造的,而且许多仍然是今天制造的。手工制造的质量取决于在慢速脚控车床上工作的技术人员,该车床可以转动适当内径的形式。该模板具有一个居中的橡胶拱或多个拱形,以形成拱形腔,以及可调节的钢制法兰,设置为面对面的尺寸。

Forty or fifty years ago all spool type flanged rubber

expansion joints were hand built and many are still being made that way today.

Hand built quality depends on a technician working at a slow speed foot

controlled lathe that turns a form of the proper inside diameter. The form has

a centered rubber arch or multiple arches to form the arch cavities, and

adjustable steel flanges that are set for the face-to-face dimension.

2、施工人员首先用橡胶衬里包裹表格,橡胶衬里越过拱门并向上朝向两侧的凸缘以形成管子。连续的橡胶浸渍轮胎帘线层同样在拱形和凸缘上方进行加工,以开始加固系统。导线在轮胎帘线上螺旋以提供径向强度,并且该过程持续到未固化的橡胶盖提供完成。

The builder begins by wrapping the form with a rubber liner

that goes over the arch and up the flanges on both sides to form the tube.

Successive layers of rubber impregnated tire cord are similarly worked up

across the arch and up the flanges to begin the reinforcement system. Wire is

spiraled over the tire cord to provide radial strength, and this process is

continued until the uncured rubber cover provides the finish.

3、然后将二次钢模板夹紧到心轴凸缘上以压缩未固化的橡胶和织物。法兰之间的主体用尼龙带包裹,以迫使多层更紧密地接触。最后,将完整的包裹组件从车床上取下并置于蒸汽室中进行固化,并在硫化后除去心轴,钢法兰和包裹物。修剪胎体并在橡胶法兰上钻孔以完成制造。

Secondary steel mold plates are then clamped to the mandrel

flanges to compress the uncured rubber and fabric. The body between the flanges

is wrapped with Nylon tape to force the multiple layers into more intimate

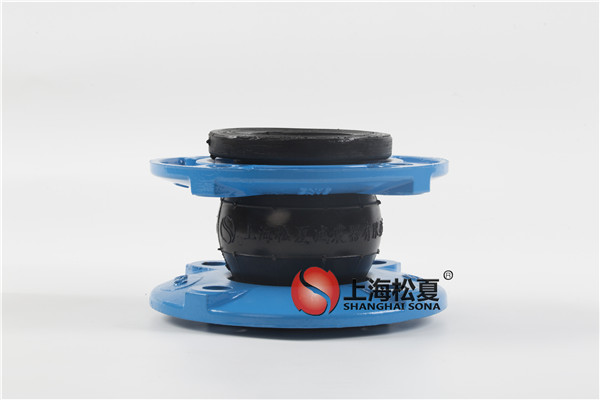

contact. Finally the complete wrapped assembly is taken off the lathe and

placed in a steam chamber for curing and the mandrel, steel flanges and

wrappings are removed after vulcanization. The carcass is trimmed and holes

drilled in the rubber flanges to complete fabrication.

4、手工制造的主要优点是相对便宜的工具以及根据特殊需求改变结构,尺寸和材料的能力。我们已经建造了大到12英尺内径的接头。这是一个非常昂贵的过程,但是带有厚壁的手工制造的接头可以承受工业服务,因为没有其他商品可以。直壁结构的有趣变化是同心和偏心的减速器系列。长度和直径变化的变化是无限的,并且在入口处具有12英寸法兰的减速器,在出口处下降至4英寸并不罕见。

The principal advantages of hand building are relatively

inexpensive tooling and the ability to vary construction, size and materials in

response to specialized demand. We have built joints as large as 12 feet I.D.

This is a slow expensive process, but the heavily walled hand built joints

withstand industrial service as no other commodity can. Interesting variations

on the straight walled construction are the concentric and eccentric family of

reducers. Variations of length and diameter change are infinite and reducers

with a 12” flange on the inlet, dropping to 4” on the outlet are not unusual.

5、我们认识到需要另一种低成本的HVAC方法,并关注轮胎行业。轮胎经受阳光和臭氧,雨水,沙漠干燥,热和冷,以及高频和冲击负荷。即使经过多年的使用,它们仍可承受高压空气而不会发生泄漏,并且经常翻新,因为墙壁非常坚固。当然,类似的结构最适合HVAC应用中的柔性管道连接器。球形膨胀节已经在海外市场上销售,并且在美国有限,所以我们的方向是工程改进而不是发明。

We recognized the need for another lower cost approach for

HVAC and looked to the tire industry. Tires withstand exposure to sunlight and

ozone, rain, desert dryness, heat and cold, as well as high frequency and shock

loads. They hold high pressure air without leakage while undergoing extreme

flexure, even after many years of service and are often retreaded because the

walls stand up so well. It would certainly follow that a similar construction

would be most suitable for flexible pipeline connectors in HVAC applications.

Spherical expansion joints were already on the market overseas and to a limited

extent in the United States, so our direction was engineering improvement

rather than invention.

6、制造过程比手动缠绕的接头简单得多。所有球形伸缩缝都采用直筒胴体制成。根据膨胀节的类型,管和帘布层以及盖子被放置在直的心轴上并且轮胎帘线反转并且绕端部缆索或刚性端环转回。将直的预制件放置在已经加工成外部形状的钢模中,而不是用尼龙手工包裹。心轴已被拆除并由气囊代替。

The manufacturing process is much simpler than for hand

wrapped joints. All spherical expansion joints are built with straight

carcasses. The tube and plies, as well as the cover, are laid up on a straight

mandrel and the tire cord reversed and turned back around end cables or rigid

end rings, depending on the style of expansion joint. The straight preform is

placed in a steel mold that has been machined to the outside shape, rather than

hand wrapped with Nylon. The mandrel has already been removed and replaced by

an air bag.

7、当借助液压机关闭模具时,会发生两件事。首先,将端部向后折叠以形成凸起的橡胶凸缘,其与钢凸缘的凸起面的直径相同。其次,当气囊膨胀时,采取球形形状以迫使胎体抵靠热钢壁。代替用于手工制造接头的蒸汽固化,固化在液压机中进行,在模具的任一侧上具有加热压板。在该模塑过程中使用的空气压力高于通常通过手工包装获得的压力,因此球形接头往往比手工包装设计更均匀。

When the mold is closed with the help of a hydraulic press,

two things take place. First, the ends are folded back to form the raised

rubber flange, which is the same diameter as the raised face of a steel flange.

Second, the spherical shape is taken when the air bag is inflated to force the

carcass out against the hot steel walls. Instead of the steam cure that is used

for the hand built joints, curing takes place in a hydraulic press with heated

platens on either side of the mold. The air pressure used in this molding

process is higher than the pressure normally obtained by hand wrapping, so

spherical joints tend to be more homogeneous than hand wrapped designs.

8、球形模制膨胀接头与最终产品中的手工缠绕(线轴型)接头以及制造方法不同。线轴型接头从线或钢环加强件获得其径向强度。拱形和橡胶法兰之间的直端部分是硬橡胶管。没有刚性加固的关节的唯一部分是拱本身。由于该设计适用于噪音和振动影响不大的工业应用,因此阀芯式伸缩接头仅适用于运动。拱形结构非常坚固,并且非常坚硬,因此压力响应的体积几乎没有变化。

Spherical molded expansion joints differ from hand wrapped

(spool type) joints in the final product as well as the method of manufacture.

Spool type joints derive their radial strength from wire or steel ring

reinforcement. The straight end sections between the arch and the rubber

flanges are stiff rubber pipe. The only part of the joint that is not rigidly

reinforced is the arch itself. Since the design is for industrial applications

where noise and vibration are of little consequence, spool type expansion

joints only address movements. The arch is very heavily reinforced and quite

stiff as well, so there is little change in volume in response to pressure.

9、手工包裹的拱门基本上是直壁的,因此当系统加压时,拱形物像波纹管一样伸展,在不受约束时会发生故障。如果膨胀节安装在具有上下两个锚的管道系统中,则它被包含并且响应于热膨胀或收缩而表现良好。

Hand wrapped arches are essentially straight walled so when

the system is pressurized, the arch stretches like a bellows toward failure

when unrestrained. If the expansion joint is installed in a piping system with

anchors both up and downstream, it is contained and performs very well in

response to thermal expansion or contraction.

10、在HVAC应用中,我们通常处理以其他方式处理的热运动。安装膨胀节使安装更简单,补偿不对中,减轻设备法兰的应力,补偿地震运动,主要是为了防止噪音和振动的传递。膨胀节通常安装在弹簧安装的设备旁边,管道也是如此。因此,管道没有固定,如果使用手动卷绕式伸缩接头,则需要安装控制杆以防止伸长失效。一旦控制杆在未固定的情况下使用,压力推力总是由控制杆承担,因此控制杆绕过膨胀节并传递噪音和振动。

In HVAC applications we are generally dealing with thermal

movements that are handled some other way. The expansion joint is installed to

make the installation simpler, compensate for misalignment, relieve the

equipment flanges of stress, compensate for seismic movement and primarily to

prevent the transmission of noise and vibration. The expansion joints are often

installed next to equipment that is spring mounted, as is the piping.

Therefore, the piping is not anchored, and if hand wrapped spool type expansion

joints were used, it would be necessary to install control rods to prevent

elongation failure. Once control rods are used in unanchored situations, the

pressure thrust is always taken by the control rods so the control rods bypass

the expansion joint and transmit both noise and vibration.

11、橡胶法兰软管在HVAC应用中使用多年,因为消除拱形使得软管对伸长率不太敏感。胴体是钢丝增强的并且在径向方向上非常坚硬,但是仍然存在拉伸约7%长度的趋势。虽然软管不会失败,拉伸产生其他问题,作为一个36”长的软管可以拉伸2 1 / 2 ”。由于它几乎不可能容纳2 1 / 2 ”伸长,软管类似地安装有上分离的或未锚定的约束系统的杆或线缆。

Rubber flanged hoses were used in HVAC applications for many

years, as eliminating the arch made the hose less sensitive to elongation. The

carcasses were wire reinforced and quite stiff in the radial direction, but

there was still a tendency to stretch about 7% of the length. While the hoses would

not fail, the stretching created other problems, as a 36” long hose could

stretch 21/2”. Since it is almost

impossible to accommodate 21/2”

elongation, hoses were similarly installed with restraining rods or cables on

isolated or unanchored systems.

12、球形膨胀节设计完全不同。球形膨胀节是球形气球。当球囊膨胀时,直径固定在给定压力下。额外的压力会使直径增大到更大但可预测的尺寸。该原理用于球形伸缩缝的设计。我们在球体的两侧切割了两个孔,并在那些位置切割了法兰。所产生的特性完全不同于线轴式膨胀节的特性,其中没有平衡力,并且压力导致破坏伸长。

Spherical expansion joint designs are entirely different. The

spherical expansion joint is a spherical balloon. When a balloon is inflated,

the diameter is fixed at a given pressure. Additional pressure will increase

the diameter to a larger but predictable dimension. This principal is used in

the design of spherical expansion joints. We cut two holes on opposite sides of

the sphere and flange at those locations. The resulting characteristics are

entirely different than those of the spool type expansion joint where there are

no counter balancing forces and the pressure causes elongation to destruction.

13、球形接头中没有钢丝加固。通过从法兰到法兰的轮胎帘线桥接来加强球体来承受压力。每根光纤的装载方式与炮塔之间悬索桥的主缆相同。悬挂电缆以类似于在膨胀接头的壁上工作的压力的方式将道路负载传递到主电缆。

There is no steel wire reinforcement in a spherical joint.

The pressure is taken by reinforcing the sphere with tire cord bridging from

flange to flange. Each fiber is loaded in much the same way as the principal

cables of a suspension bridge between turrets. The hanging cables transmit the

roadway loading to the main cable in a fashion similar to the pressure working

on the wall of the expansion joint.

14、通过改变帘布层的数量并相对于膨胀接头的轴线设定制造角度,可以控制端部的膨胀和移动。虽然它们是真正的膨胀节,但我们经常将这种球形装置描述为连接器,因为它们结合了软管和膨胀节最理想的特性。

By varying the number of ply layers and setting the angle of

manufacture in relation to the axis of the expansion joint, the swell and

movement of the ends can be controlled. While they are truly expansion joints,

we often describe this line of spherical devices as connectors, as they combine

the most desirable properties of both hose and expansion joints.

15、球形设计对由压力产生的推力产生平衡力,使得这些部分在压力下膨胀到给定的可预测长度。通过这种方式,它们就像软管一样,但延伸很小。在未锚定的位置,例如弹簧安装设备的管道,在压力下有预测长度的预扩展指令。这可以防止弹簧压缩或泵或设备基础的移动。然而,如果引入锚固件,它们可以响应于振动或热力而被压缩,延伸,横向或成角度地移动到比大多数线轴型伸缩接头更大的程度。

The spherical design develops a balancing force to the thrust

generated by the pressure, so that the sections expand to a given predictable

length under pressure. In this way they act like hose, but with very little

extension. In unanchored locations, such as pipelines to spring mounted

equipment, there are pre-extension instructions to the predicted length under

pressure. This prevents compression of the springs or shifting of the pump or

equipment foundations. However, they can be compressed, extended, moved

transversely or angularly in response to vibratory or thermal forces to a greater

degree than most spool type expansion joints if anchors are introduced.

16、当我们开始制造球形连接器时,我们相信,后来在各种测试中证明,我们首次使用的设备可以在阀芯式接头不能时有效降低流体传输噪音。球形,特别是双球形设计的整个胎体响应于由声音引起的压力脉动引起的压力变化而呼吸。当波通过膨胀接头时,这用于阻尼流体中的这种压力波。

When we started manufacturing spherical connectors, we

believed, and later proved in various tests that for the first time we had a

device that would effectively reduce fluid transmitted noise when spool type

joints do not. The entire carcass of spherical, and particularly double sphere,

designs breathes in response to the changing pressure caused by sound induced

pressure pulsations. This serves to damp out this pressure wave in the fluid as

the wave passes through the expansion joint.

17、我们不断修改这些设计,以消除对控制杆或控制电缆的需求。我们最新的系列(Safeflex)非常有效。不需要在所有大小1全压控制棒1 / 2 ”到14”单和双球体。在大多数压力下通过24“也可以省略控制。

We have continually modified these designs to eliminate the

need for control rods or control cables. Our very latest series (Safeflex) is

extremely effective in doing so. Control rods are not needed at full pressure

in all the sizes 11/2” through 14”

both single and double sphere. Controls may also be omitted at most pressures

through 24”.

18、所有球形伸缩接头都配有延性或钢制浮动法兰,与主体无关。通过一体式法兰固定在法兰槽中的嵌入式柔性电缆珠或通过向下压在刚性外壳钢环上的开口法兰来固定主体。它实际上是形成密封的连接器的末端,不需要垫圈。然而,重要的是,球形接头与固体表面配合,而不是像在唯特利服务中使用的那些空心法兰。简单的间隔凸缘可以解决这类问题。

All spherical expansion joints are furnished with ductile or

steel floating flanges that are independent of the body. The body is retained

either by means of an embedded flexible cable bead held into a flange groove by

a one piece flange or by split flanges that bear down on a rigid encased steel

ring. It is actually the end of the connector that forms the seal and no

gaskets are required. It is important, however, that the spherical joint mates

with a solid surface and not a hollow flange such as those used in victaulic

service. A simple spacer flange can solve this type of problem.

19、由于钢或韧性凸缘在每端都是浮动的,因此在安装这些接头和排列孔时不会出现问题,并且在安装过程中不可能出现扭曲变形。法兰通常钻至150或300磅。美国的ASA标准,但它们也有DIN,JIN,PIN,韩国,英国E或F以及其他世界标准。

Since the steel or ductile flanges are floating at each end,

there is never a problem in installing these joints and lining up the holes and

there is no possibility of torsional distortion during installation. Flanges

are normally drilled to 150 or 300 Lb. ASA standards in the United States, but

they are also available in DIN, JIN, PIN, Korean, British E or F as well as

other world standards.

20、由于我们的球形连接器用于噪音和振动,最常用的设备是双球。在我们的工作中,我们只使用单个球体,其中空间排除了双重,或者我们的客户正在使用其他公司的较低规格。3 / 4 ”到2”球形状与螺纹端部制成。

Because our spherical connectors are used for noise and

vibration, the most commonly specified device is the twin sphere. In our work

we only use the single sphere where space rules out the double or where our

client is working to lesser specifications by other firms. 3/4” through 2” sphericals are made with threaded ends.

微信二维码

微信二维码